Machine Grab

Machine Grab

LED Bulbs Aging Line Machine

Machine Details

-

Machine ID : ma795447dynhh

-

Machine Purpose : sale

-

Machine Condition : Used

-

Machine Category : electrical equipment

-

Machine Sub-Category : Electrical Testing Equipment

-

Machine Country : Pakistan

-

Machine City : Faisalabad

-

Views : 185

-

Manufacturer : Grandseed

Model : Gx-101

Made In: Made in China

Bought Year : 2020

Description

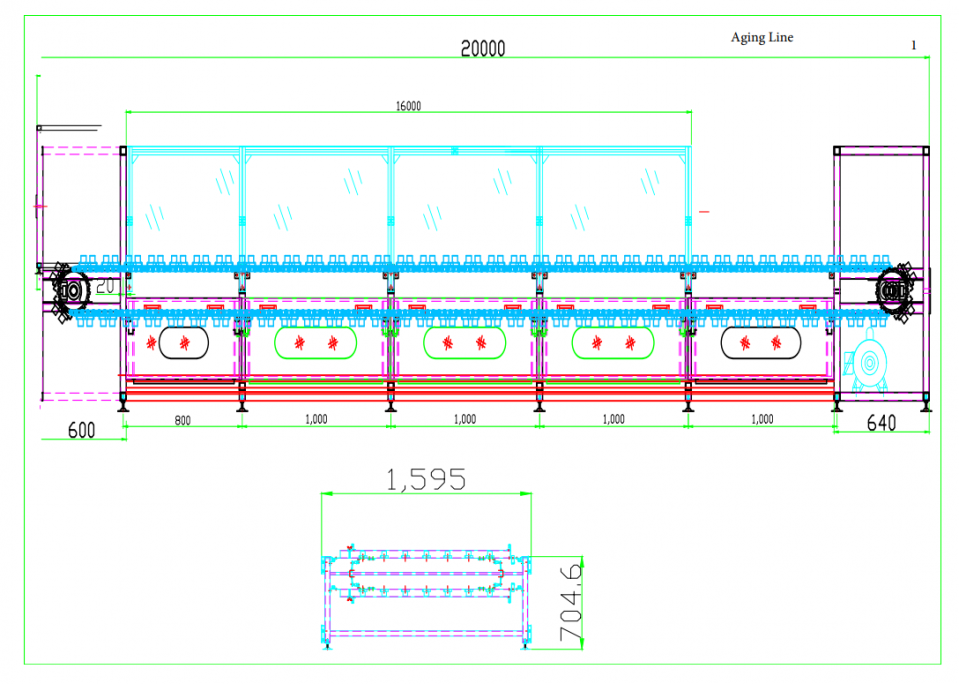

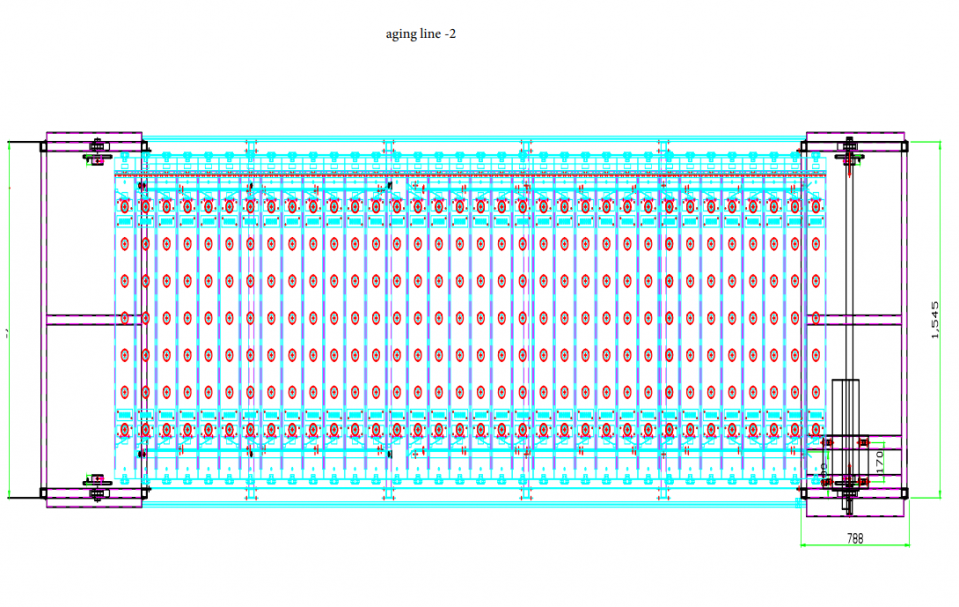

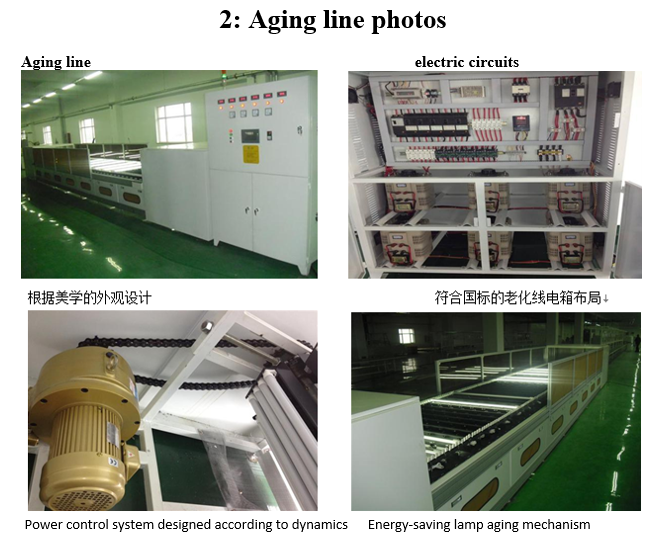

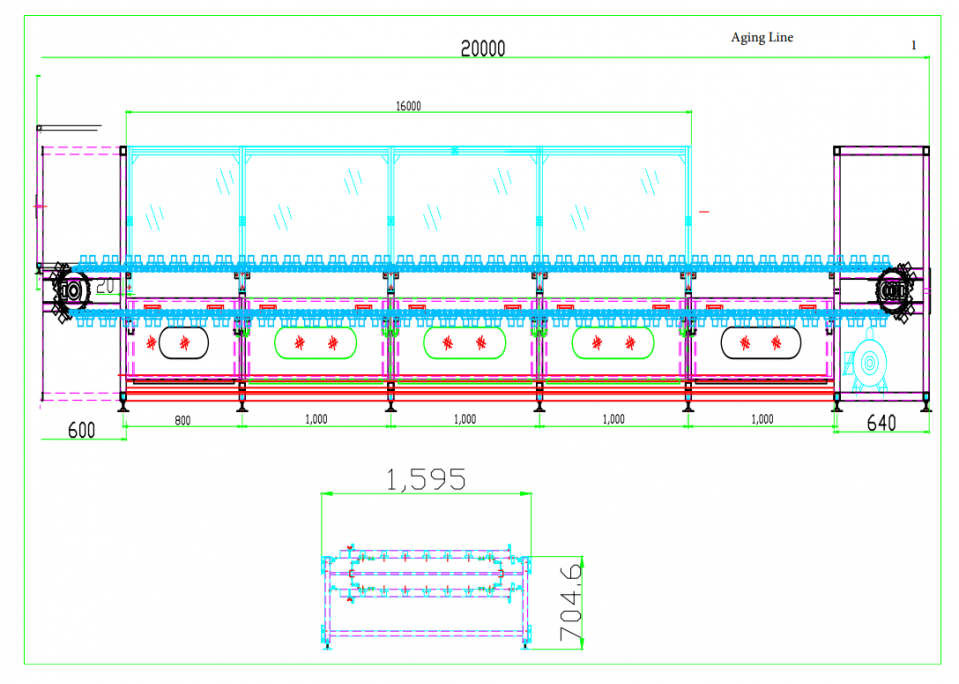

Brand Name: Grandseed Installation: Included in Price Contact: 0302xxxxxxx- Usman Ch. Price Options: 1: Pay upfront 25Lac and buy 2: Pay initial deposit 15lac and Buy/install machine. Rest within 3-6 months. Full Price 27-30lac. 3: Exchange Possible with a Car Specifications Length: L20m * W1.620m * 1.270m 1. The motor uses a bending station Wanxin 2.2KW three-phase motor, 1 : 200 gearhead, of 3HP inverter frequency step-less speed of 0 - 2M / min adjustable, the aging time of 0-4 hours adjustable. 2. Adopt a 1-inch T17 tooth double pitch sprocket with φ 50 main shaft and tensioning mechanism as a transmission device. 1. Fuselage and frame: the frame is welded with 40 × 40 × 1.5mm square steel tubes; the fuselage is made of aluminum alloy profiles for 130 × 23 aging line. The height of the working surface and the ground is adjustable at 750 ± 20mm 2. The head and tail guards are made by 1.5mm cold plate bending. The The lower shading plate is made of a 1.5mm cold plate and is equipped with a 3mm thick brown plexiglass observation window, one meter in one section, and two buckles in each section. 3. Conveyor chain: Adopt C212A double pitch single ear high strength double hole chain produced by Hangzhou Chain Factory. 30 * 30 national standard angle steel is used as a supporting guide rail; there are two layers up and dow 4. Chain board: 2.0mm cold rolled to bend 148 × 1390 × 57mm, each chain plate mounted a unipolar open space, 16 the E27 five lamp holder clip, four groups positionable T8 fluorescent lamp holder. Install a two-way conductive brush (copper) on the bottom. The chain plate is sprayed in black. 5. Daily output: There are 240 chain plates in the line; each chain plate is equipped with 16 E27 five-lamp clip lamp holders and T8 lamp holder fixtures. (The lamp holder fixture can be adjusted to 300, 600, 900, or 1200MM ) 4 pairs, 3840 bulb bulbs or 960 fluorescent tubes (full line, 1 hour a week, 8 hours: bulb 3840 * 8 = 30720 or fluorescent lamps: 960 * 8 = 7680 ) (capacity depends on aging time) 1. Electric cabinet: 1.5 mm cold plate is bent and rolled into 730 × 1250 × 1800mm, 40 × 40 × 1.5mm iron square tube support, arranged in two layers. The upper layer is the instrument, small conventional control elements, and the lower layer is the voltage regulator 2. Control element: equipped with an ammeter, digital display voltmeter, and indicator lamp to display input voltage and three-phase current. The system is controlled by Mitsubishi PLC and 7 -inch Xinjie touch screen, and the impact of aging time and start-stop transportation can be adjusted in the touch screen operation interface; 3. An emergency stop switch is installed on the electric box and the wire body for the emergency stop. Equipped with three-color warning lights to show the operating status of the equipment.